As a drill stem valve specialist, Sub-drill is in the ideal position to supply, manage and maintain your critical valve assets.

By offering a first class service and quick response to client needs for a number of years, Sub-drill continue to grow and maintain a trusted client base for the repair, servicing, testing and new product supply to end users and major drilling contractors. Sub-drill has been overhauling, repairing, assembling, testing and supplying drill stem valves for many years and has recently invested in additional footprint of its valve repair centre, along with its in-house skill set, technicians and resources.

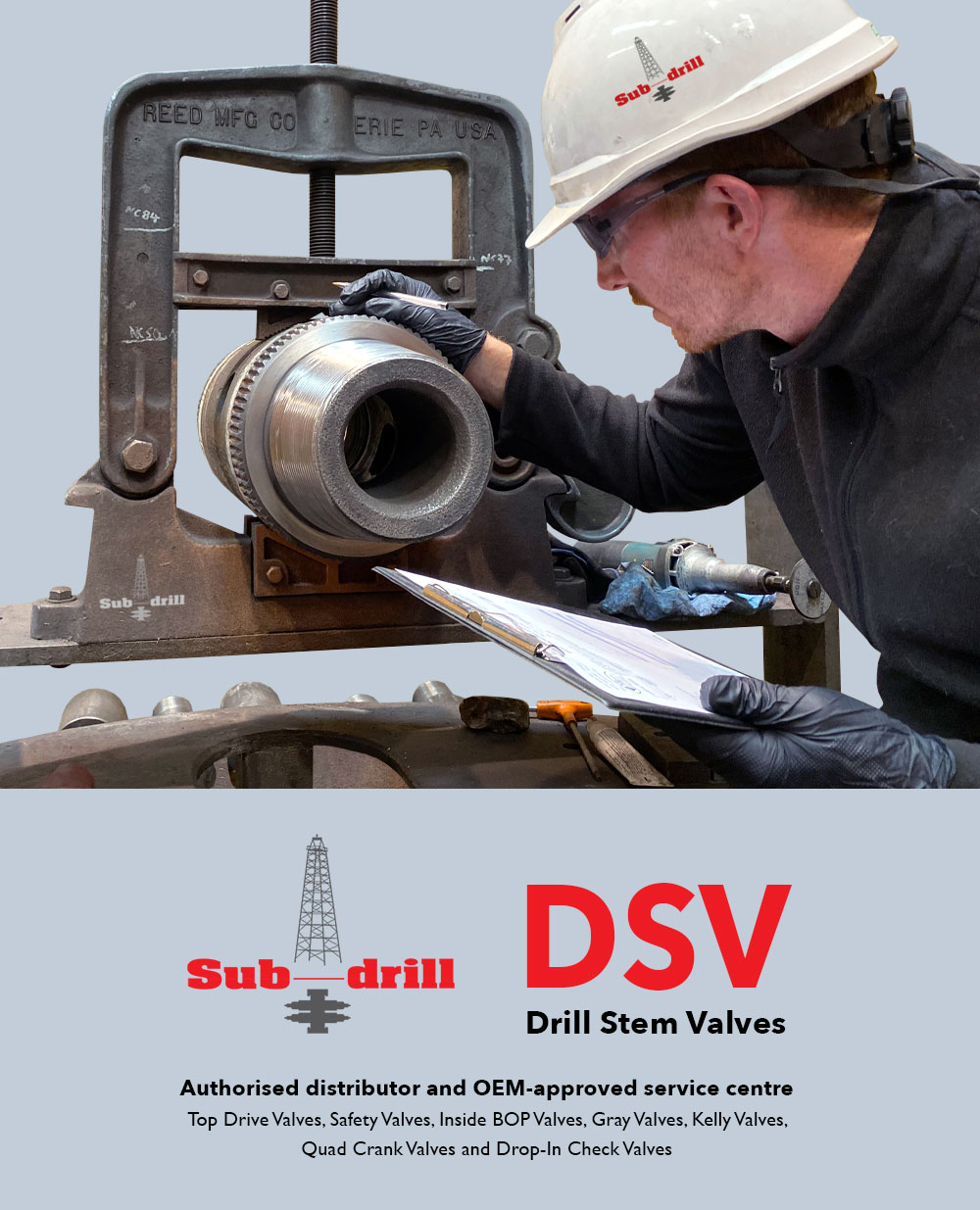

Sub-drill is the authorised distributor and OEM-approved service centre for US Manufacturer Global Manufacturing Inc covering Europe and Africa. The design, engineering and manufacture of Global’s drill stem valves are carried out to the highest quality standards using Finite Element Analysis FEA, resulting in extremely reliable valves, proven over many years to last in the most demanding of offshore environments.

Authorised Distributor

As an authorised distributor, Sub-drill supplies a comprehensive range of OEM standard drill stem valves including Top Drive Valves, Safety Valves, Inside BOP Valves, Gray Valves, Kelly Valves, Quad Crank Valves and Drop-In Check Valves.

Approved Repair Centre

Sub-drill provide a comprehensive in-house inspection, repair and re-certification service for all drill stem valve types including other OEM Manufacturers at our state of the art facility in Westhill, Aberdeenshire in the UK. Sub-drill ensures that all valves are repaired and tested to appropriate industry standards, and we are able to follow up on servicing at specified life-cycle intervals to ensure the integrity of the valves in use offshore. Additionally, Sub-drill provides the means to test valves offshore using our compact portable Sub-drill DSV™ Test Stand. By utilising the DSV™ Test Stand, drill stem valve testing can be carried out quickly and safely offline, in parallel with BOP testing or drilling.

Strip-down, Repair and Pressure Test Service

It’s vital that pressure control equipment is properly cleaned and inspected during maintenance to ensure its service life, reliability and safety.

Sub-drill provides a comprehensive strip-down, repair and pressure test service with quick turnaround.

• Full-service inspection report and costs prior to commencement of repair work

• Pressure testing up to 30,000 psi

• 3rd Party NDT Inspection

• Pressure Testing Service for Customer Equipment

• Replacement Valve Supply

Global Manufacturing Inc.

Benefits

• API Spec 7 Approved

• Manufactured to NS-1 Specification where applicable

• API – Q1 Monitored

• API – QC System

• Design Analysis c/w FEA

• DNV & ABS Certification is available if required

Product Range

• Top Drive Valves

• Safety Valves

• Inside BOP Valves

• Gray Valves

• Kelly Valves (One and Two Piece)

• Quad Crank Valves

• Drop-In Check Valves

For more information, please contact sales@subdrill.co.uk

Further reading

• Drill Stem Services

• Drill String Valves

• Safety & Downtime Critical